Our Process

Our Process is What Makes Fotoforms so Much Better!

Fotoforms are cut by laser, which has several important advantages:

- The laser automatically polishes and seals the edges of our products for years of beauty and durability.

- The laser allows us to easily cut even the smallest interior spaces that a saw can’t reach.

- The Laser lets us use less distracting, CLEAR acrylic backing instead of colors (a saw leaves a severely scratched edge which is hidden by using colored acrylic).

- The laser allows us to offer significant quantity discounts because the cut-path can be easily repeated when producing multiples of the same item.

Fotoforms are cut by laser, which has several important advantages:

- We feel that experienced artists give Fotoforms a real advantage in determining how your product should be cut to looks as beautiful as possible.

- Real artists on staff allow us to offer professional graphics design services if needed.

Fotoforms use super-thick, premium clarity, high gloss laminate (for most products 11×14 and smaller). We use a thinner version with luster option for larger projects:

- Lamination is very important for long term protection of your photos and provides a level of beauty that makes a real difference.

- Optional luster lamination is helpful for larger items such as puzzles and lifesize so that flash-glare is minimized if someone wants to take a photo of the item.

Fotoforms has the experience and equipment to offer many construction methods:

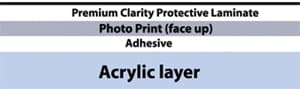

Surface Mounting:

Your photo is covered with a protective laminate and mounted to acrylic. This method gives cut-outs and pop-outs a beautiful surface finish.

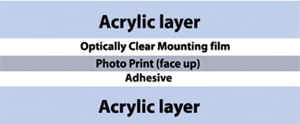

2nd Surface Mounting:

This method is used to protect your image behind a layer of acrylic. A good choice for signs on public display because of ease of cleaning and protection from vandalism.

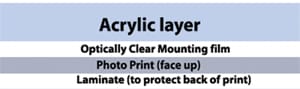

Sandwich Mounting:

Sandwich Mounting traps your image between layers of acrylic for ultimate durability. A great choice when the piece will be handled by many people, such as a museum puzzle.